|

An American Classic: The

Albany Slip Two-Handled Jug (2003)

Rowe Pottery Works, famous for

creating museum-quality reproductions of early American pottery,

now offers a limited production jug with authentic Albany Slip

glazing.

Albany Slip glaze was made from a

natural glacial clay discovered in Albany, New York in the early

1800s. "Slip Glaze" is the potter's term for a glaze made from

clay mixed with water.

Albany Slip glaze is characterized

by its deep-brown color. It was common on earthenware,

stoneware and salt-glaze pottery throughout the 1800s. It is

the natural brown often associated with bean pots. It can be

altered to produce a wide range of earth tones.

Durable and decorative, Albany Slip

was often used as an interior glaze on salt-glaze pottery. It

melted smoothly to form an impermeable glass coating, perfect

for storing liquids and for ease of cleaning. Its popularity

spread among potters throughout North America with the expansion

of the railroad system.

Once common, Albany Slip is now a

rare substance.

Much other clay was mined in the Midwest during this time and

also became known as Albany Slip, however, it is not true

Albany Slip clay. The

original Albany mine closed in 1986 due to difficulties in

extracting the clay. Since then, commercial supplies have been

exhausted. Only small stocks remain in private hands of potters

who treasured the colors of true Albany Slip.

Rowe Pottery Works is using

its own remaining inventory of true Albany Slip clay, one of the

last known stock, in making of this special historical Two

Handled Jug. In order to reserve our stock, we are introducing

only one Albany Slip collectible per year.

This jug truly represents a

bygone era of American pottery. It is an expression of the

quality and craftsmanship of Albany Slip pottery of the 1800s.

It is grand in size, holding approximately two gallons and

weighing more than 10 pounds. It is decorated with a primitive

bird sprig, a hand-combed pattern, two pulled handles and glazed

with true Albany Slip clay on the outside.

Each Jug will have a

variation of the "orange-peel" effect due to the salt glazing

process. This variation enhances the uniqueness of each pitcher

- no two will be exactly alike! A collector's treasure, this

showpiece will be available for a limited time.

Albany Slip Two Handled Jug - 15"H x 9"W

(Sorry -

Sold Out)

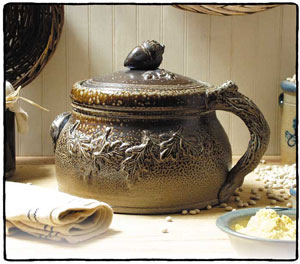

Albany

Slip Bean Pot - Limited Edition for 2004 Albany

Slip Bean Pot - Limited Edition for 2004

The Albany Slip collection

continues in 2004 with the introduction of the Bean Pot. Third

in a series of handcrafted pottery decorated with true Albany

Slip clay and fired in the traditional salt-glaze manner. The

2004 Albany Slip Bean Pot comes with a recipe card for Grandma

Rowe's Beans and a Certificate of Authenticity signed by

Jim Rowe that includes the history of the bean pot and

the important relationship it had with the 19th century potter.

Albany Slip Bean Pot - 9"H x 12"W

(Sorry -

Sold Out)

The Potter and the Bean Pot

The potter has always been a valuable resource in rural

communities. Pottery was the most popular product produced by

the potter, but not the only one. Radiant heat created by the

wood burning kilns was a by product that was used by the women

of the community to bake beans. As we know, beans take many

hours to cook and since the potter would stoke his kiln with

wood for 24 to 36 hours at a time to reach the ideal firing

temperature, this created a great opportunity for beans to bake.

The bean pot shape was even created for baking next to a kiln.

It was made of stoneware that the potter crafted from clay he

gathered from a nearby riverbed or creek. The looped handle made

it easy for the potter to use his hooked rod to move the bean

pot from hot spots by the kiln. The properties of stoneware

could withstand the heat of the kiln and would help create an

even bake. The stoneware would also keep the beans warm long

after it was taken home. Rowe Pottery Works 2004 Albany Slip

Bean Pot is decorated with true Albany Slip clay and fired in

the traditional salt-glaze manner. Our craftsmen have added

original touches like oak leaves, acorn lid and bark lug and

handle to commemorate the forests that kept many of our

forefather's kilns burning for days on end. |